-

Bahasa Indonesia

-

English

Oleh: Vincent Gaspersz, Lean Six Sigma Master Black Belt & Certified Management System Lead Specialist

- APICS (www.apics.org) Certified Fellow in Production and Inventory Management (CFPIM) and Certified Supply Chain Professional (CSCP);

- International Quality Federation (www.iqf.org) Six Sigma Master Black Belt (SSMBB);

- ASQ (www.asq.org) Certified Manager of Quality/Organizational Excellence (CMQ/OE), Certified Quality Engineer (CQE), Certified Quality Auditor (CQA), Certified Six Sigma Black Belt (CSSBB), Certified Quality Improvement Associate (CQIA);

- Registration Accreditation Board (www.exemplarglobal.org) Certified Management System Lead Specialist (CMSLS).

- Senior Member of American Society for Quality (Member #: 00749775), International Member of American Production and Inventory Control Society (Member #: 1023620), and Senior Member of Institute of Industrial and Systems Engineers (Member #: 880194630).

- Insinyur Profesional Utama (IPU) – Persatuan Insinyur Indonesia (PII)

Saya kurang meyakini kurikulum atau silabus mata kuliah Supply Chain Management di Indonesia (baik pada level S1 maupun S2) TELAH memenuhi standar internasional dalam pembelajaran Supply Chain Management yang sesungguhnya.

Silakan bandingkan dengan kurikulum dari IISE (Institute of Industrial and Systems Engineers) Body of Knowledge atau APICS (d/h American Production and Inventory Management Society) CSCP (Certified Supply Chain Professional) Body of Knowledge di sini:

Body of Knowledge tentang Supply Chain Management dari IISE:

Supply Chain Management Body of Knowledge (Sumber: Institute of Industrial & Systems Engineers, USA, Industrial Engineering BoK, September 2016)

Dalam Industrial Engineering BoK terbaru (September 2016) dikemukakan 12 area pengetahuan, yaitu:

- Work Design and Measurement

- Operations Research and Analysis

- Engineering Economic Analysis

- Facilities Engineering and Energy Management

- Quality & Reliability Engineering

- Ergonomics and Human Factors

- Operations Engineering & Management

- Supply Chain Management

- Engineering Management

- Safety

- Information Engineering

- Related Topics

- Product Design & Development

- Systems Design & Engineering

Informasi berikut adalah berkaitan dengan Supply Chain Management:

- Supply Chain Management

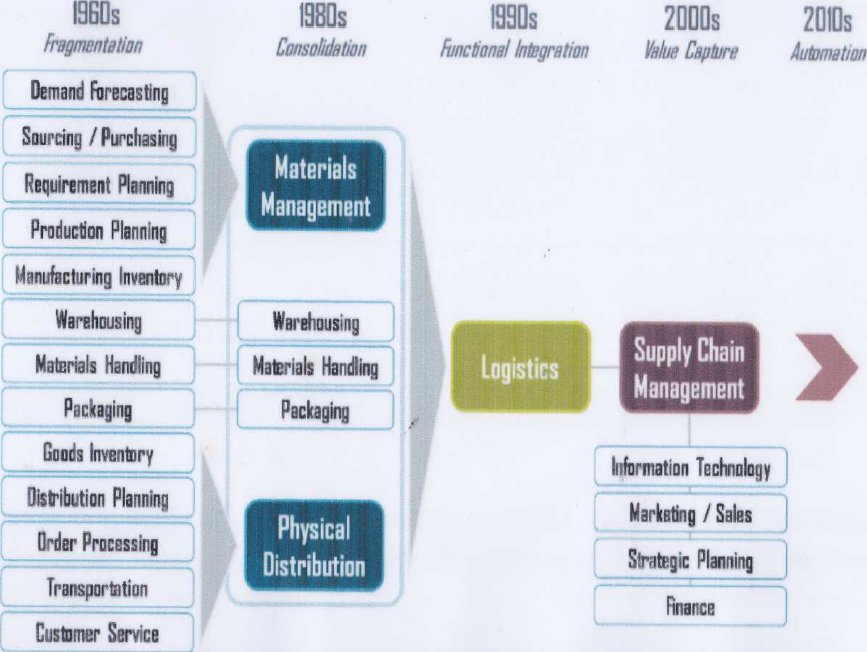

Supply Chain Management (SCM) mencakup pergerakan, produksi, penyimpanan bahan baku, persediaan dalam proses (WIP — work in process), barang jadi, dan jasa dari titik asal sampai ke titik konsumsi atau penggunaan. Pemasok, produsen, perantara, toko, dan perusahaan jasa terlibat dalam pengiriman produk dan pelayanan (service) kepada konsumen akhir dalam rantai pasokan (supply chain).

KOMPETENSI Minimum yang HARUS dipahami dalam Supply Chain Management adalah:

A. Supply Chain Management Fundamentals

- Supply chain management processes

- Make / buy analysis

- Adding value to organizations

- Importance of aligning supply chain strategy with corporate strategy

- Supply chain risk management strategies

- Assessment and measurement of effectiveness of supply chains

- Fundamentals of green supply chain initiatives

B. Building Competitive Operations, Planning, and Logistics

- Dynamics within the supply chain to optimize performance and increase profitability

- Designing agility into a supply chain

- Lean principles in a supply chain

- Assessing the value of demand

- Reducing complexity in demand planning

- Establishing collaborations to replace or improve demand estimates

- Including supply chain factors in product design

- Cost

- Packaging

- Aligning distribution and transportation options with supply chain strategy

- 3PL (Third Party Logistics) and 4PL (Fourth Party Logistics) service providers

- Supply chain network design

- Tiers

- Number, size, and location of facilities

C. Reverse logistics

- Shared-resource, closed-loop systems

- Capacity utilization from multi-directional product flow

D. Managing Product Flow

- Inventory control methodologies (see Operations Engineering & Management knowledge area)

- Material handling systems

- Work sourcing management

- Transportation management

- Mode/Carrier selection

- Consolidation

- Vehicle routing

E. Managing Customer Relationships

- Customer Stratification based on their profiles and needs

- Understanding customer loyalty and lifetime value of a customer

- Establishing measures of customer satisfaction

- Supplier support and oversight

F. Managing Supplier Relationships

- Insourcing vs. outsourcing decisions

- On-shore

- Off-shore

- Strategic importance of purchasing and supplier relationships

- Supplier scorecard systems

- Managing the supplier lifecycle

- Supplier selection

- Contracting

- Onboarding

- Order-to-cash

- Decommissioning a supplier

- Customer data

- Service performance

- Increasing value to suppliers and customers

- Selection of and understanding Tier 2, 3, etc. suppliers

- Supplier risk management

REFERENCES:

- Supply Chain Management Best Practices. Blanchard, David. John Wiley & Sons, 2nd Edition. 2010.

- Supply Chain Management: Processes, Partnerships, Performance. Lambert,

Douglas M. Supply Chain Management Institute, 3rd Edition. 2008. - Supply Chain Management for Engineers. Huang, Samuel H. CRC Press. 2013.

- Designing and Managing the Supply Chain. Simchi-Levi, David, Kaminsky, Philip., and Simchi-Levi, Edith. McGraw Hill, 3rd Edition. 2008.

- Supply Chain Management: Strategy, Planning, and Operations. Chopra, Sunil, and Meindl, Peter. Pearson, 6th Edition, 2015.

- Supply Chain Engineering: Models and Applications. Ravindran, A. Ravi, and Warsing, Donald. CRC Press, 2012.

- Supply Chain Science. Hopp, Wallace. Waveland Press, 2011.

- Supply Chain Logistics Management. Bowersox, Donald, Closs, Donald., and Cooper, Bixby.McGraw Hill, 4th Edition. 2012.

- Managing Closed-Loop Supply Chains. Flapper, Simme Douwe., van Nunen, Jo, van Wassenhove, Luk N (Editors). Springer, 2005.

- Introduction to Logistics Systems Management. Ghiani, Gianpaolo, Laporte, Gilbert., Musmanno, Roberto. John Whiley & Sons, 2nd Edition, 2013.

- A taxonomy for Supply Chain Management Literature, Capar, Ismail, Ulengin, Fusun., Reisman, Arnold, (April 6, 2004).

Silakan download paper GRATIS di sini: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=531902

Body of Knowledge dari APICS CSCP:

Memahami APICS CSCP Body of Knowledge

Sumber: http://www.apics.org/credentials-education/credentials/cscp

Area pengetahuan No. 8 tentang Supply Chain Management dalam Industrial Engineering BoK yang dipublikasi oleh IISE (Institute of Industrial & Systems Engineers) pada September 2016 itu dapat didalami lagi melalui memperoleh gelar profesional dalam bidang Supply Chain Management dari APICS (d/h American Production and Inventory Control Society) sehingga membuktikan KOMPETENSI kita melalui memperoleh APICS CSCP (Certified Supply Chain Professional).

Masa berlaku sertifikat APICS CSCP adalah lima tahun, sehingga kita harus memperpanjang setiap lima tahun sekali melalui menyerahkan nilai kredit (credit point) sejumlah 75 points dari berbagai aktivitas profesional. Jika tidak maka kita harus mengikuti ujian ulang lagi.

Ujian APICS CSCP mencakup tiga modul berikut:

- Module 1 – Supply Chain Design

- Module 2 – Supply Chain Planning and Execution

- Module 3 – Supply Chain Improvements and Best Practices

Note: Ujian APICS CSCP dilakukan melalui computer-based testing (CBT) at Pearson VUE test centers, yang berlokasi di seluruh dunia.

Persyaratan Mengikuti Ujian APICS CSCP:

- Memiliki tiga tahun pengalaman kerja dalam bidang yang terkait dengan APICS CSCP BoK, atau

- Minimum lulus S1 (memiliki Bachelor’s degree), atau

- Pemegang gelar profesional dari APICS

KOMPETENSI INTI

Mulai tahun 2016 KOMPETENSI INTI yang diuji adalah:

Module 1: Supply Chain Design—Book 1 of 2:

Module 1 Introduction

Section A: Develop the Supply Chain Strategy

- Chapter 1: Inputs to Supply Chain Strategy

- Topic 1: Business Model

- Topic 2: External Inputs to Supply Chain Strategy

- Chapter 2: Supply Chains and Supply Chain Strategy

- Topic 1: Supply Chains and Supply Chain Management

- Topic 2: Objectives of Supply Chain Management Strategy

- Topic 3: Supply Chain Strategy: Alignment and Value Proposition

- Topic 4: Supply Chain Strategy: Core Capabilities

- Topic 5: Supply Chain Strategy: Cost Structure and Revenue Model

- Topic 6: Supply Chain Maturity

- Chapter 3: Resolving Misalignments or Gaps

- Topic 1: Reasons Misalignments or Gaps Occur

- Topic 2: Recognizing Misalignments or Gaps

- Topic 3: Resolving Misalignments or Gaps

- Chapter 4: Tools and Techniques

- Topic 1: Macro and Micro Economic Considerations

- Topic 2: Accounting and Financial Reporting Information

- Topic 3: Strategic Analysis Tools

Module 1—Supply Chain Design—Book 2 of 2:

Section B: Design the Supply Chain

- Chapter 1: Business Considerations

- Topic 1: Market, Financial, and Product Research and Modeling

- Topic 2: Reverse and Specialized Supply Chains

- Topic 3: Collaboration with Supply Chain Partners

- Chapter 2: Supply Chain Design

- Topic 1: Supply Chain Design and Configuration

- Topic 2: Inventory, Technology, and Metrics Design

- Topic 3: Fulfillment Strategies Considering Market Requirements

- Topic 4: Product Design for New Products or Requirements

- Topic 5: Supply Chain Network Optimization

- Chapter 3: Technology Design

- Topic 1: Information Technology and Supply Chain Management

- Topic 2: Electronic Business Considerations

- Topic 3: Key Technology Applications

- Topic 4: Data Acquisition and Management

- Chapter 4: Implementation Tools: Communications and Projects

- Topic 1: Communication Considerations

- Topic 2: Project Management Considerations

- Topic 3: Project Management Process Groups

Module 2—Supply Chain Planning and Execution—Book 1 of 2

Module 2 Introduction

Section A: Procure and Deliver

- Chapter 1: Demand Management

- Topic 1: Components of Demand Management

- Topic 2: Forecasting Demand

- Topic 3: Demand Prioritization

- Topic 4: Demand Management Functional Responsibilities and Interfaces

- Chapter 2: Operations Planning and Control

- Topic 1: Master Planning and Sales and Operations Planning (S&OP)

- Topic 2: Master Scheduling

- Topic 3: Controlling Priorities

- Topic 4: Materials and Inventory

- Topic 5: Capacity Management, Planning, and Control

- Chapter 3: Inventory Management

- Topic 1: The Need for Inventory

- Topic 2: Aggregate and Item Inventory Management

- Topic 3: Flow of Inventory

- Topic 4: Functions of Inventory

- Topic 5: Inventory-Related Cost Categories

- Topic 6: Effects of Inventory on the Financial Statements

- Topic 7: Inventory Planning

- Topic 8: Inventory Control

- Chapter 4: Supply Management

- Topic 1: Total Cost of Ownership (TCO)

- Topic 2: Make-Versus-Buy Analysis

- Topic 3: Range of Buyer-Supplier Relationships

- Topic 4: Developing Supply Plans

- Topic 5: Contracting

- Topic 6: Expediting

- Chapter 5: Logistics

- Topic 1: Logistics Introduction

- Topic 2: Logistics Objectives and Considerations

- Topic 3: Warehouse Management Introduction

- Topic 4: Warehousing Objectives and Considerations

- Topic 5: Warehouse Capacity Forecasting and Planning

- Topic 6: Materials Handling

- Topic 7: Tradeoffs between Warehousing and Transportation Processes

- Topic 8: Transportation Objectives and Considerations

- Topic 9: Transportation Capacity Forecasting and Planning

- Topic 10: Use of Logistics Service Providers

- Topic 11: Modes of Transportation and Considerations for Selection

- Topic 12: Expediting Processes

- Topic 13: Delivery Patterns

- Chapter 6: Monetary, Regulatory, and Trade Considerations

- Topic 1: Currency Considerations and Funds Flow

- Topic 2: Regulatory Requirements

- Topic 3: Trade Considerations

Section B: Manage the Relationship with Supply Chain Partners

- Chapter 1: Segmentation

- Topic 1: Segmentation and Customer-Driven Marketing

- Topic 2: Market Segmentation

- Topic 3: Customer Segmentation

- Topic 4: Segmentation of Suppliers or Other Supply Chain Partners

- Chapter 2: Customer Relationship Management (CRM)

- Topic 1: Introduction to Customer Relationship Management (CRM)

- Topic 2: CRM Strategy

- Topic 3: Customer Selection or Segmentation

- Topic 4: Customer Relationship Types

- Topic 5: Performance Management

- Topic 6: Technology Usage

- Chapter 3: Supplier Relationship Management (SRM)

- Topic 1: Introduction to Supplier Relationship Management (SRM)

- Topic 2: Supplier Selection

- Topic 3: Supplier Relationship Types

- Topic 4: Performance Management

- Topic 5: Technology Usage

- Chapter 4: Linkages between CRM and SRM

- Topic 1: How Various Organizations Can Leverage CRM and SRM

- Topic 2: Negotiation and Collaboration

- Topic 3: Terms and Conditions

- Topic 4: Contracts and Enforceability

Section C: Manage Reverse Logistics

- Chapter 1: Reverse Logistics

- Topic 1: Reverse Logistics Introduction

- Topic 2: Strategy and Design for Reverse Logistics

- Topic 3: Reverse Logistics Benefits and Costs

- Chapter 2: Waste Considerations

- Topic 1: Waste Hierarchy

- Topic 2: Waste Exchange and Hazardous Waste

Module 3: Supply Chain Improvement and Best Practices

Module 3 Introduction

Section A: Comply with Standards, Regulations, and Sustainable Best Practices

- Chapter 1: International Standards and Regulatory Compliance

- Topic 1: Import/Export, Intellectual Property, and Licensing Compliance

- Topic 2: International Accounting, Tax, and Labor Laws

- Chapter 2: Corporate Social Responsibility Considerations

- Topic 1: Triple Bottom Line

- Topic 2: The UN Global Compact and the Global Reporting Initiative

- Topic 3: Other Sustainability Guidelines

- Chapter 3: Social, Environmental, Safety, and Quality Accreditations and Certifications

- Topic 1: Standards, Accreditations, and Certifications

- Topic 2: Quality Accreditations and Certifications

- Topic 3: Environmental Accreditations and Certifications

- Topic 4: Social Accreditations and Certifications

- Topic 5: Safety Accreditations and Certifications

Section B: Manage Risk in the Supply Chain

- Chapter 1: Risk Identification

- Topic 1: Risk Management

- Topic 2: Risk Identification and Documentation

- Topic 3: Supply Chain Risk

- Chapter 2: Risk Assessment and Classification

- Topic 1: Qualitative Risk Analysis

- Topic 2: Quantitative Risk Analysis

- Chapter 3: Risk Response

- Topic 1: Risk Response Planning

- Topic 2: Preventive and Contingent Action Plans for the Supply Chain

- Topic 3: Business Continuity and Plan Implementation

- Chapter 4: Security, Regulatory, and Compliance Concerns

- Topic 1: Security and Regulatory Concerns

- Topic 2: Risk Standards

Section C: Measure, Analyze, and Improve the Supply Chain

- Chapter 1: Supply Chain Metrics

- Topic 1: Supply Chain Strategy and Metrics Selection

- Topic 2: Customer-Focused Metrics

- Topic 3: Financial Metrics

- Topic 4: Operational Metrics

- Chapter 2: Measuring Performance and Customer Service

- Topic 1: Measuring and Communicating Performance

- Topic 2: SCOR Performance Measures

- Topic 3: Measuring Operational and Financial Performance

- Topic 4: Measuring Customer Service Levels

- Chapter 3: Continuous Improvement and Change Management

- Topic 1: Continuous Improvement

- Topic 2: Lean and Just-In-Time

- Topic 3: Other Continuous Improvement Philosophies

- Topic 4: Change Management

APICS CSCP References

Bagi mereka yang akan menguji KOMPETENSI mereka dari APICS CSCP, disarankan untuk membaca buku-buku referensi berikut yang disarankan oleh Komite Ujian APICS CSCP.

- APICS Dictionary, 15th edition.

- Supply Chain Logistics Management, 4th edition, McGraw-Hill, 2013 – Donald Bowersox, David Closs, M. Bixby Cooper.

- A Guide to the Project Management Body of Knowledge, 5th edition – Project Management Institute, Inc. 2013.

- Supply Chain Risk Management: An Emerging Discipline. CRC Press, 2014, Gregory L. Schlegel and Robert J. Trent.

- Strategic Supply Chain Management: The Five Core Disciplines for Top Performance, 2nd edition, Mc-Graw-Hill Education, 2013. Shoshanah Cohen and Joseph Roussel.

- Principles of Supply Chain Management – Richard E. Crandall, William R. Crandall, Charlie C. Chen.

- Introduction to Supply Chain Management Technologies, 2nd edition – David F. Ross, CFPIM.

- Designing and Managing the Supply Chain: Concepts, Strategies and Case Studies, 3rd edition – David Simchi-Levi, Philip Kaminsky, and Edith Simchi-Levi.

- UN Global Compact Brochure, UN Global Compact Office 2014. Free download.

- UN Global Compact Management Model 2010 – Deloitte Touche Tohmatsu, Welcome message by Georg Kell, forward by John Connolly. Free download.

- The G4 Sustainability Reporting Guidelines, Global Reporting 2011. Free

download. - Security Risk Assessment for Transport Operations: A Practical Guide for Small to Medium-Sized Organisations, State of Victoria. Free download.

Additional Resources

These articles were selected by the APICS CSCP Certification Exam Committee and address the core concepts and competencies related to the APICS CSCP exam.

- APICS Supply Chain Strategy Report

- Don’t Let Your Supply Chain Control Your Business

- Finding your Strategy in the New Landscape

- Seven Myths to Beat Before They Beat You

- The Ten Commandments of Legal Risk Management

- Unprofitable Customers and Their Management

- Best Value Supply Chains: A key Competitive Weapon for the 21st Century

- Don’t Tweak Your Supply Chain—Rethink It End to End

- Fudging the Supply Chain to Hit the Number: Five Common Practices that Sacrifice the Supply Chain and What Financial Analysts Should Ask about Them

Informasi di atas dapat dijadikan pembanding apakah seorang lulusan Teknik Industri yang memiliki area konsentrasi Supply Chain Management TELAH memiliki kompetensi untuk menghadapi ujian profesional APICS CSCP itu?

Hal ini penting mengingat persentase kelulusan dari ujian APICS CSCP tidak terlalu tinggi, sedangkan biaya dan waktu persiapan yang banyak.

Bagaimanapun, jika kita memiliki gelar profesional APICS CSCP, maka kompetensi kita dalam bidang Supply Chain Management TELAH diakui secara internasional, sehingga kita MAMPU berkompetisi di pasar global berkaitan dengan area pengetahuan Supply Chain Management.

Pembelajaran GRATIS dan bersifat tambahan jika dirasakan masih kurang tentang pemahaman Supply Chain Management boleh mengakses material berikut:

http://accessengineeringlibrary.com/browse/supply-management-handbook-7th-ed#fullDetails

How Far is the Supply Chain Management Learning in Indonesia?

By: Vincent Gaspersz, Lean Six Sigma Master Black Belt & Certified Management System Lead Specialist

- APICS (www.apics.org) Certified Fellow in Production and Inventory Management (CFPIM) and Certified Supply Chain Professional (CSCP);

- International Quality Federation (www.iqf.org) Six Sigma Master Black Belt (SSMBB);

- ASQ (www.asq.org) Certified Manager of Quality/Organizational Excellence (CMQ/OE), Certified Quality Engineer (CQE), Certified Quality Auditor (CQA), Certified Six Sigma Black Belt (CSSBB), Certified Quality Improvement Associate (CQIA);

- Registration Accreditation Board (www.exemplarglobal.org) Certified Management System Lead Specialist (CMSLS).

- Senior Member of American Society for Quality (Member #: 00749775), International Member of American Production and Inventory Control Society (Member #: 1023620), and Senior Member of Institute of Industrial and Systems Engineers (Member #: 880194630).

- Insinyur Profesional Utama (IPU) – Persatuan Insinyur Indonesia (PII) // Primary Professional Engineer – Association of Indonesian Engineers

I am unsure that the curricula or syllabi of Supply Chain Management courses in Indonesia (both at undergraduate and graduate levels) have met the real international standards in Supply Chain Management learning.

Please compare them with the curriculum of IISE (Institute of Industrial and Systems Engineers) Body of Knowledge Systems or of APICS (American Production and Inventory Management Society) CSCP (Certified Supply Chain Professional) Body of Knowledge below:

IISE’s Body of Knowledge on Supply Chain Management:

Supply Chain Management Body of Knowledge (Source: Institute of Industrial & Systems Engineers, USA, Industrial Engineering BoK, September 2016)

Within the latest Industrial Engineering BoK (September 2016), 12 areas of knowledge are being put forward, namely:

- Work Design and Measurement

- Operations Research and Analysis

- Engineering Economic Analysis

- Facilities Engineering and Energy Management

- Quality & Reliability Engineering

- Ergonomics and Human Factors

- Operations Engineering & Management

- Supply Chain Management

- Engineering Management

- Safety

- Information Engineering

- Related Topics

- Product Design & Development

- Systems Design & Engineering

The following information is related to Supply Chain Management:

- Supply Chain Management

Supply Chain Management (SCM) includes movement, production, raw material storage, in-process inventory (WIP — work in process), finished goods, and services from the point of origin to the point of consumption/use. Suppliers, manufacturers, intermediaries, shops, and service firms are involved in the delivery of products and services to end-consumers within the supply chain.

Minimum COMPETENCIES that MUST be understood in Supply Chain Management are:

A. Supply Chain Management Fundamentals

- Supply chain management processes

- Make / buy analysis

- Adding value to organizations

- Importance of aligning supply chain strategy with corporate strategy

- Supply chain risk management strategies

- Assessment and measurement of effectiveness of supply chains

- Fundamentals of green supply chain initiatives

B. Building Competitive Operations, Planning, and Logistics

- Dynamics within the supply chain to optimize performance and increase profitability

- Designing agility into a supply chain

- Lean principles in a supply chain

- Assessing the value of demand

- Reducing complexity in demand planning

- Establishing collaborations to replace or improve demand estimates

- Including supply chain factors in product design

- Cost

- Packaging

- Aligning distribution and transportation options with supply chain strategy

- 3PL (Third Party Logistics) and 4PL (Fourth Party Logistics) service providers

- Supply chain network design

- Tiers

- Number, size, and location of facilities

C. Reverse logistics

- Shared-resource, closed-loop systems

- Capacity utilization from multi-directional product flow

D. Managing Product Flow

- Inventory control methodologies (see Operations Engineering & Management knowledge area)

- Material handling systems

- Work sourcing management

- Transportation management

- Mode/Carrier selection

- Consolidation

- Vehicle routing

E. Managing Customer Relationships

- Customer Stratification based on their profiles and needs

- Understanding customer loyalty and lifetime value of a customer

- Establishing measures of customer satisfaction

- Supplier support and oversight

F. Managing Supplier Relationships

- Insourcing vs. outsourcing decisions

- On-shore

- Off-shore

- Strategic importance of purchasing and supplier relationships

- Supplier scorecard systems

- Managing the supplier lifecycle

- Supplier selection

- Contracting

- Onboarding

- Order-to-cash

- Decommissioning a supplier

- Customer data

- Service performance

- Increasing value to suppliers and customers

- Selection of and understanding Tier 2, 3, etc. suppliers

- Supplier risk management

REFERENCES:

- Supply Chain Management Best Practices. Blanchard, David. John Wiley & Sons, 2nd Edition. 2010.

- Supply Chain Management: Processes, Partnerships, Performance. Lambert,

Douglas M. Supply Chain Management Institute, 3rd Edition. 2008. - Supply Chain Management for Engineers. Huang, Samuel H. CRC Press. 2013.

- Designing and Managing the Supply Chain. Simchi-Levi, David, Kaminsky, Philip., and Simchi-Levi, Edith. McGraw Hill, 3rd Edition. 2008.

- Supply Chain Management: Strategy, Planning, and Operations. Chopra, Sunil, and Meindl, Peter. Pearson, 6th Edition, 2015.

- Supply Chain Engineering: Models and Applications. Ravindran, A. Ravi, and Warsing, Donald. CRC Press, 2012.

- Supply Chain Science. Hopp, Wallace. Waveland Press, 2011.

- Supply Chain Logistics Management. Bowersox, Donald, Closs, Donald., and Cooper, Bixby.McGraw Hill, 4th Edition. 2012.

- Managing Closed-Loop Supply Chains. Flapper, Simme Douwe., van Nunen, Jo, van Wassenhove, Luk N (Editors). Springer, 2005.

- Introduction to Logistics Systems Management. Ghiani, Gianpaolo, Laporte, Gilbert., Musmanno, Roberto. John Whiley & Sons, 2nd Edition, 2013.

- A taxonomy for Supply Chain Management Literature, Capar, Ismail, Ulengin, Fusun., Reisman, Arnold, (April 6, 2004).

Please download the FREE article here: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=531902

Body of Knowledge of APICS’ CSCP:

Understanding APICS’ CSCP Body of Knowledge

Source: http://www.apics.org/credentials-education/credentials/cscp

That knowledge area number 8 on Supply Chain Management in Industrial Engineering BoK published by IISE (Institute of Industrial & Systems Engineers) in September 2016 can be further explored through obtaining a professional degree in Supply Chain Management from APICS (American Production and Inventory Control Society); thus proving your own COMPETENCE through obtaining APICS CSCP (Certified Supply Chain Professional) designation.

The APICS CSCP certificate’s validity period is for five years; therefore, we must extend the certificate in every five years by submitting credit points (of 75 points) from various professional activities. Otherwise, we would have to retake the exam.

The APICS’ CSCP exam includes the following three modules:

- Module 1 – Supply Chain Design

- Module 2 – Supply Chain Planning and Execution

- Module 3 – Supply Chain Improvements and Best Practices

Note: The APICS’ CSCP exams are performed through computer-based testing (CBT) at Pearson VUE test centers, located worldwide.

The requirement to take APICS’ CSCP Exam is:

- Memiliki tiga tahun pengalaman kerja dalam bidang yang terkait dengan APICS CSCP BoK, atau

Having three years of work experience in a field related to APICS CSCP BoK, or

- Having Bachelor’s degree, or

- Holding a professional designation from APICS

CORE COMPETENCIES

Beginning in 2016, the CORE COMPETENCIES tested are:

Module 1: Supply Chain Design—Book 1 of 2:

Module 1 Introduction

Section A: Develop the Supply Chain Strategy

- Chapter 1: Inputs to Supply Chain Strategy

- Topic 1: Business Model

- Topic 2: External Inputs to Supply Chain Strategy

- Chapter 2: Supply Chains and Supply Chain Strategy

- Topic 1: Supply Chains and Supply Chain Management

- Topic 2: Objectives of Supply Chain Management Strategy

- Topic 3: Supply Chain Strategy: Alignment and Value Proposition

- Topic 4: Supply Chain Strategy: Core Capabilities

- Topic 5: Supply Chain Strategy: Cost Structure and Revenue Model

- Topic 6: Supply Chain Maturity

- Chapter 3: Resolving Misalignments or Gaps

- Topic 1: Reasons Misalignments or Gaps Occur

- Topic 2: Recognizing Misalignments or Gaps

- Topic 3: Resolving Misalignments or Gaps

- Chapter 4: Tools and Techniques

- Topic 1: Macro and Micro Economic Considerations

- Topic 2: Accounting and Financial Reporting Information

- Topic 3: Strategic Analysis Tools

Module 1—Supply Chain Design—Book 2 of 2:

Section B: Design the Supply Chain

- Chapter 1: Business Considerations

- Topic 1: Market, Financial, and Product Research and Modeling

- Topic 2: Reverse and Specialized Supply Chains

- Topic 3: Collaboration with Supply Chain Partners

- Chapter 2: Supply Chain Design

- Topic 1: Supply Chain Design and Configuration

- Topic 2: Inventory, Technology, and Metrics Design

- Topic 3: Fulfillment Strategies Considering Market Requirements

- Topic 4: Product Design for New Products or Requirements

- Topic 5: Supply Chain Network Optimization

- Chapter 3: Technology Design

- Topic 1: Information Technology and Supply Chain Management

- Topic 2: Electronic Business Considerations

- Topic 3: Key Technology Applications

- Topic 4: Data Acquisition and Management

- Chapter 4: Implementation Tools: Communications and Projects

- Topic 1: Communication Considerations

- Topic 2: Project Management Considerations

- Topic 3: Project Management Process Groups

Module 2—Supply Chain Planning and Execution—Book 1 of 2

Module 2 Introduction

Section A: Procure and Deliver

- Chapter 1: Demand Management

- Topic 1: Components of Demand Management

- Topic 2: Forecasting Demand

- Topic 3: Demand Prioritization

- Topic 4: Demand Management Functional Responsibilities and Interfaces

- Chapter 2: Operations Planning and Control

- Topic 1: Master Planning and Sales and Operations Planning (S&OP)

- Topic 2: Master Scheduling

- Topic 3: Controlling Priorities

- Topic 4: Materials and Inventory

- Topic 5: Capacity Management, Planning, and Control

- Chapter 3: Inventory Management

- Topic 1: The Need for Inventory

- Topic 2: Aggregate and Item Inventory Management

- Topic 3: Flow of Inventory

- Topic 4: Functions of Inventory

- Topic 5: Inventory-Related Cost Categories

- Topic 6: Effects of Inventory on the Financial Statements

- Topic 7: Inventory Planning

- Topic 8: Inventory Control

- Chapter 4: Supply Management

- Topic 1: Total Cost of Ownership (TCO)

- Topic 2: Make-Versus-Buy Analysis

- Topic 3: Range of Buyer-Supplier Relationships

- Topic 4: Developing Supply Plans

- Topic 5: Contracting

- Topic 6: Expediting

- Chapter 5: Logistics

- Topic 1: Logistics Introduction

- Topic 2: Logistics Objectives and Considerations

- Topic 3: Warehouse Management Introduction

- Topic 4: Warehousing Objectives and Considerations

- Topic 5: Warehouse Capacity Forecasting and Planning

- Topic 6: Materials Handling

- Topic 7: Tradeoffs between Warehousing and Transportation Processes

- Topic 8: Transportation Objectives and Considerations

- Topic 9: Transportation Capacity Forecasting and Planning

- Topic 10: Use of Logistics Service Providers

- Topic 11: Modes of Transportation and Considerations for Selection

- Topic 12: Expediting Processes

- Topic 13: Delivery Patterns

- Chapter 6: Monetary, Regulatory, and Trade Considerations

- Topic 1: Currency Considerations and Funds Flow

- Topic 2: Regulatory Requirements

- Topic 3: Trade Considerations

Section B: Manage the Relationship with Supply Chain Partners

- Chapter 1: Segmentation

- Topic 1: Segmentation and Customer-Driven Marketing

- Topic 2: Market Segmentation

- Topic 3: Customer Segmentation

- Topic 4: Segmentation of Suppliers or Other Supply Chain Partners

- Chapter 2: Customer Relationship Management (CRM)

- Topic 1: Introduction to Customer Relationship Management (CRM)

- Topic 2: CRM Strategy

- Topic 3: Customer Selection or Segmentation

- Topic 4: Customer Relationship Types

- Topic 5: Performance Management

- Topic 6: Technology Usage

- Chapter 3: Supplier Relationship Management (SRM)

- Topic 1: Introduction to Supplier Relationship Management (SRM)

- Topic 2: Supplier Selection

- Topic 3: Supplier Relationship Types

- Topic 4: Performance Management

- Topic 5: Technology Usage

- Chapter 4: Linkages between CRM and SRM

- Topic 1: How Various Organizations Can Leverage CRM and SRM

- Topic 2: Negotiation and Collaboration

- Topic 3: Terms and Conditions

- Topic 4: Contracts and Enforceability

Section C: Manage Reverse Logistics

- Chapter 1: Reverse Logistics

- Topic 1: Reverse Logistics Introduction

- Topic 2: Strategy and Design for Reverse Logistics

- Topic 3: Reverse Logistics Benefits and Costs

- Chapter 2: Waste Considerations

- Topic 1: Waste Hierarchy

- Topic 2: Waste Exchange and Hazardous Waste

Module 3: Supply Chain Improvement and Best Practices

Module 3 Introduction

Section A: Comply with Standards, Regulations, and Sustainable Best Practices

- Chapter 1: International Standards and Regulatory Compliance

- Topic 1: Import/Export, Intellectual Property, and Licensing Compliance

- Topic 2: International Accounting, Tax, and Labor Laws

- Chapter 2: Corporate Social Responsibility Considerations

- Topic 1: Triple Bottom Line

- Topic 2: The UN Global Compact and the Global Reporting Initiative

- Topic 3: Other Sustainability Guidelines

- Chapter 3: Social, Environmental, Safety, and Quality Accreditations and Certifications

- Topic 1: Standards, Accreditations, and Certifications

- Topic 2: Quality Accreditations and Certifications

- Topic 3: Environmental Accreditations and Certifications

- Topic 4: Social Accreditations and Certifications

- Topic 5: Safety Accreditations and Certifications

Section B: Manage Risk in the Supply Chain

- Chapter 1: Risk Identification

- Topic 1: Risk Management

- Topic 2: Risk Identification and Documentation

- Topic 3: Supply Chain Risk

- Chapter 2: Risk Assessment and Classification

- Topic 1: Qualitative Risk Analysis

- Topic 2: Quantitative Risk Analysis

- Chapter 3: Risk Response

- Topic 1: Risk Response Planning

- Topic 2: Preventive and Contingent Action Plans for the Supply Chain

- Topic 3: Business Continuity and Plan Implementation

- Chapter 4: Security, Regulatory, and Compliance Concerns

- Topic 1: Security and Regulatory Concerns

- Topic 2: Risk Standards

Section C: Measure, Analyze, and Improve the Supply Chain

- Chapter 1: Supply Chain Metrics

- Topic 1: Supply Chain Strategy and Metrics Selection

- Topic 2: Customer-Focused Metrics

- Topic 3: Financial Metrics

- Topic 4: Operational Metrics

- Chapter 2: Measuring Performance and Customer Service

- Topic 1: Measuring and Communicating Performance

- Topic 2: SCOR Performance Measures

- Topic 3: Measuring Operational and Financial Performance

- Topic 4: Measuring Customer Service Levels

- Chapter 3: Continuous Improvement and Change Management

- Topic 1: Continuous Improvement

- Topic 2: Lean and Just-In-Time

- Topic 3: Other Continuous Improvement Philosophies

- Topic 4: Change Management

APICS CSCP References

For those who will test their COMPETENCIES from APICS’ CSCP, it is advisable to read the following reference books that are suggested by the APICS’ CSCP Exam Committee.

- APICS Dictionary, 15th edition.

- Supply Chain Logistics Management, 4th edition, McGraw-Hill, 2013 – Donald Bowersox, David Closs, M. Bixby Cooper.

- A Guide to the Project Management Body of Knowledge, 5th edition – Project Management Institute, Inc. 2013.

- Supply Chain Risk Management: An Emerging Discipline. CRC Press, 2014, Gregory L. Schlegel and Robert J. Trent.

- Strategic Supply Chain Management: The Five Core Disciplines for Top Performance, 2nd edition, Mc-Graw-Hill Education, 2013. Shoshanah Cohen and Joseph Roussel.

- Principles of Supply Chain Management – Richard E. Crandall, William R. Crandall, Charlie C. Chen.

- Introduction to Supply Chain Management Technologies, 2nd edition – David F. Ross, CFPIM.

- Designing and Managing the Supply Chain: Concepts, Strategies and Case Studies, 3rd edition – David Simchi-Levi, Philip Kaminsky, and Edith Simchi-Levi.

- UN Global Compact Brochure, UN Global Compact Office 2014. Free download.

- UN Global Compact Management Model 2010 – Deloitte Touche Tohmatsu, Welcome message by Georg Kell, forward by John Connolly. Free download.

- The G4 Sustainability Reporting Guidelines, Global Reporting 2011. Free

download. - Security Risk Assessment for Transport Operations: A Practical Guide for Small to Medium-Sized Organisations, State of Victoria. Free download.

Additional Resources

These articles were selected by the APICS CSCP Certification Exam Committee and address the core concepts and competencies related to the APICS CSCP exam.

- APICS Supply Chain Strategy Report

- Don’t Let Your Supply Chain Control Your Business

- Finding your Strategy in the New Landscape

- Seven Myths to Beat Before They Beat You

- The Ten Commandments of Legal Risk Management

- Unprofitable Customers and Their Management

- Best Value Supply Chains: A key Competitive Weapon for the 21st Century

- Don’t Tweak Your Supply Chain—Rethink It End to End

- Fudging the Supply Chain to Hit the Number: Five Common Practices that Sacrifice the Supply Chain and What Financial Analysts Should Ask about Them

The above information can be used as comparison to determine whether an Industrial Engineering graduate, who has a concentration area in Supply Chain Management, has the competence to take that APICS’ CSCP professional exam.

This is important given the passing percentage of from APICS’ CSCP exam is not very high, while its costs and preparation time are high.

Nevertheless, if we have an APICS’ CSCP professional degree, then our competence in the field of Supply Chain Management would HAVE BEEN recognized internationally; hence, we would be ABLE TO compete in the global market related to the area of Supply Chain Management knowledge.

The following link contains additional FREE learning materials for those who feel the need to understand more about Supply Chain Management:

http://accessengineeringlibrary.com/browse/supply-management-handbook-7th-ed#fullDetails